As we head into the warmer months I wanted to touch on Air Conditioning repair, maintenance and diagnostic. Lets start with the Basics of how Air Conditioning works in automobiles. The Air Conditioning system consists of many components and sensors. The system is sealed and is vacuumed down to remove all the air from the system and then charged with Freon. The Freon maybe R12, R134 or R1234YF. Without getting too bogged down in the specifics the compressor pumps the Freon through several components and generates cool air in the cabin via the Evaporator core. The system must be charged to a specific amount to cool properly. This amount is determined by the size of the system. Any over or under charge of the system can cause diminished cooling.

Air conditioning system components

- Compressor

- Condenser

- Expansion Valve

- Hoses

- Accumulator

- Pressure switches

- Evaporator core

- Orifice Tube

Diagnostic Procedure

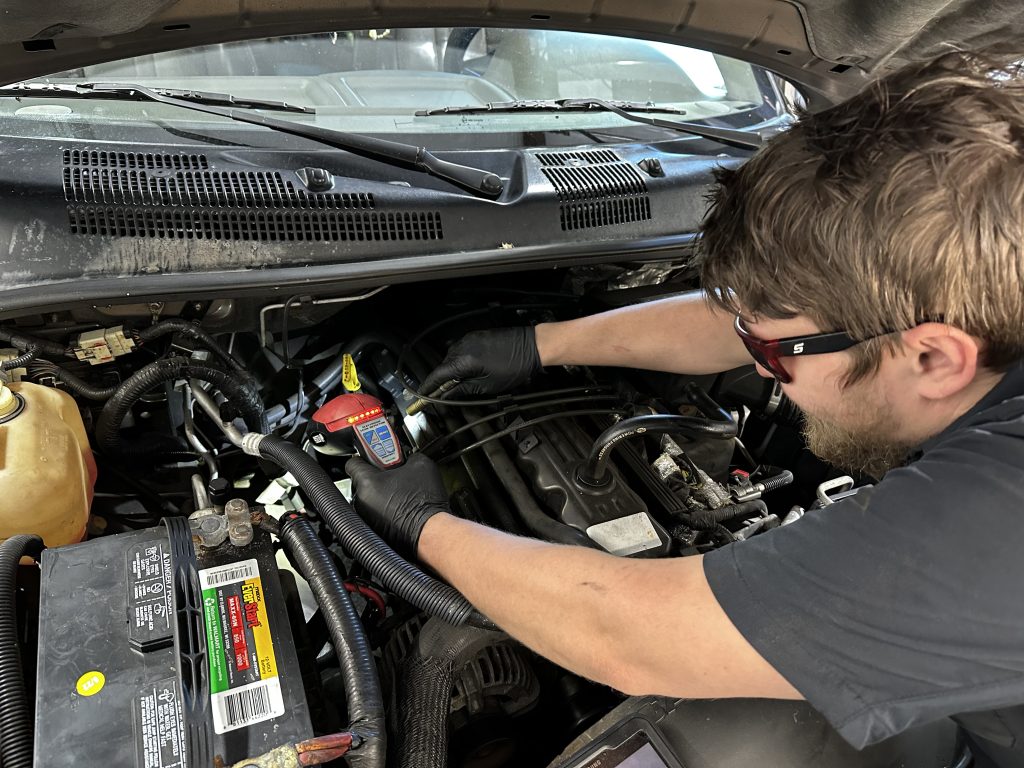

The first step in determining the cause of a inoperative Air Conditioning system to to Evacuate the Freon from the system and measure that amount against the proper charge for the system. Example if your Vehicle requires 1.25 Lbs of Freon, the first step is to confirm that the system has this amount. If it is over or under filled it can cause diminished cooling in the system. Once we have determined the charge in the system we document the amount of Freon, add Ultra violet dye and charge it back to the proper amount. Once the system has the proper charge now we can accurately test the system. If the system is low the dye will help us pinpoint the leak.

If the system is fully charged when evacuated we can check that box off as potential cause of diminished cooling. We can now test the components in the Air conditioning system and find the failed part. If the system is low we can begin inspecting to find the Leak in the system

Finding Leaks

There are 2 common ways to find leaks in Air Conditioning systems. Inspecting with an UV light to search for dye, or to use a refrigerant leak detector sometimes called a sniffer to “smell” Freon gas leaking. This tool can be really helpful to find tiny leaks that may not show the UV dye. These tools are used to inspect closely every component in the AC system. Sometimes the leak is so small that we recommend the customer drive the vehicle for a week and return to the shop to see if the leak has presented itself.

Common Issues

The most common issue with AC systems is a leak. Freon is an invisible Gas that is under high pressure and the leak must be found and repaired. Repairing a leak in a high pressure system can be tricky, as when you install a new part into an old system the leak may migrate and find another weak spot in the system. It is very common to repair one leak only to have a vehicle return after an AC repair to find another old component has sprung a leak once the system is charged back up and holding high pressure.

Another Common issue is a failed electrical component. The AC system uses pressure switches to ensure proper pressure in the system. These switches prevent operation of the AC if the pressure is too high or too low. If one of these switches are reading inaccurately the system will not operate. There are several other issue that can cause the AC to not function as designed.

If your having a problem with your AC system give a trusted shop a call. If your in the East TN area reach out to us at the shop 865-691-3400

— Joshua Shook Sr.